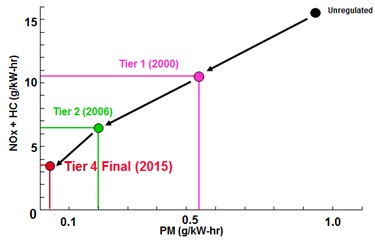

Tier 4 Final makes a significant leap in reducing these emissions with a 55% reduction in NOx emissions and an 80% reduction in PM emissions compared to Tier 2 levels.

Tier 4 Final makes a significant leap in reducing these emissions with a 55% reduction in NOx emissions and an 80% reduction in PM emissions compared to Tier 2 levels.

This is a significant change for high horsepower markets – but with Cummins, it’s simple!

Tier 4 Final affects the Cummins high horsepower engine family, which includes the QSK19, QSK23, QST30, QSK38, QSK50, QSK60, QSK78 and QSK95. These engine platforms will optimize in-cylinder diesel combustion and utilize Selective Catalytic Reduction (SCR) to meet Tier 4 Final emissions, all the while maximizing productivity and maintaining the reliability customers have come to depend on across a wide range of machines, rugged duty cycles and tough environments.

Building on the legendary reliability of Cummins industrial engines, Cummins Tier 4 Final engines and aftertreatment components form a fully integrated engine system from intake to exhaust. This improved combustion technology controls PM and the SCR reduces NOx emissions, allowing Cummins Tier 4 engines to meet Tier 4 emissions with no major changes to the engine itself or service intervals - all while reducing fuel consumption and maintaining Tier 2 levels of performance and durability.

For the first time in nearly ten years, diesel engines above 751 hp will be faced with a change in the technology used to reduce emissions from the engine. On January 1, 2015, EPA Tier 4 Final Nonroad emissions regulations take effect, regulating all diesel engines above 751 hp (illustrated in the chart to the right). These regulations set emission limits for particulate matter (PM) and oxides of nitrogen (NOx), which are key components in acid rain and smog.