Three Cummins hydrogen production facilities that are helping build a green economy

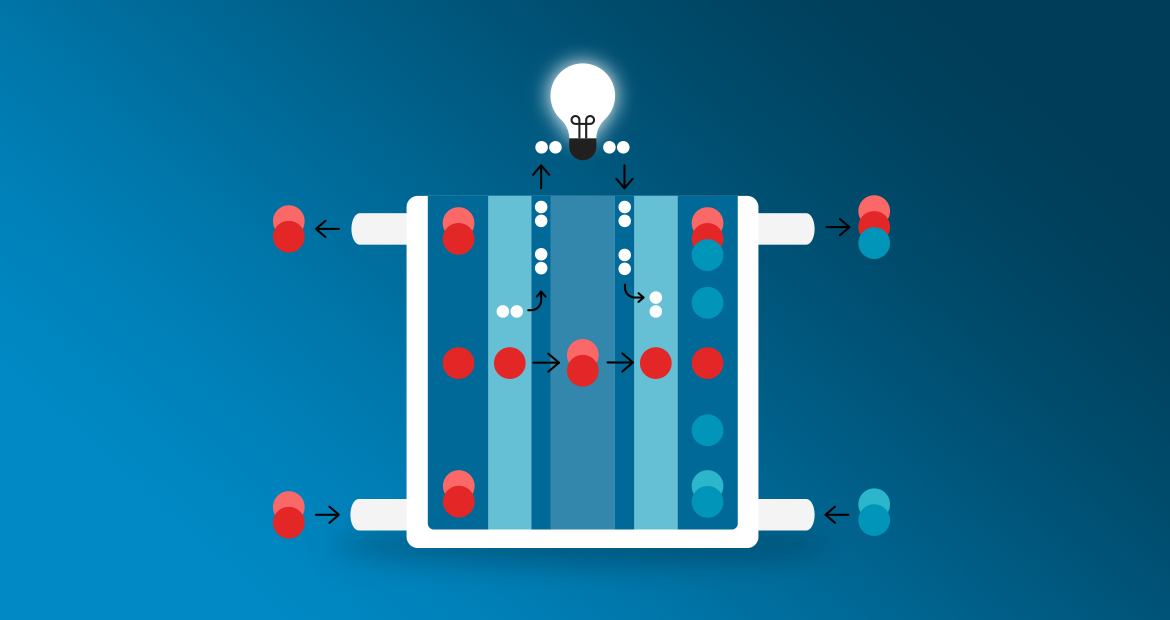

To decrease the negative impacts of climate change and decarbonize the power sector, renewable technologies like wind and solar have emerged as key ingredients to providing a solution. But integrating these intermittent energy sources into the power grid can be challenging. This is where electrolyzers come. Hydrogen makes other forms of renewable energy more viable by providing efficient and portable storage of electricity. Electrolyzers enable the production of hydrogen, which can be used by industrial clients or stored and used to power applications, including trains, buses, trucks and more, and Cummins has hundreds operational in the field.

Take wind turbines as an example. Electrolyzers can economically convert wind energy to hydrogen and oxygen in a process called water electrolysis. Water electrolysis produces no harmful emissions — only oxygen and hydrogen. Hydrogen is produced when electricity prices are low which is typically the case when wind energy is abundant. Then, the hydrogen can be stored or transported to customers. Hydrogen’s potential for storing and transporting energy makes it a key enabler of a global transition to renewable energy.

Cummins made a bold entry into the hydrogen economy in September 2019 with the acquisition of Hydrogenics, a global hydrogen fuel cells and electrolyzer technology manufacturer, and Cummins continues to make quick progress in innovating new products and applications in the hydrogen space, including three electrolyzers that are making an impact:

HyBalance – Denmark: Supplying clean hydrogen to 1,000 fuel cell vehicles

Cummins, along with its partners, established this 1.2-megawatt proton exchange membrane (PEM) electrolyzer site more than two years ago in Denmark. The site supplies clean hydrogen to customers of Air Liquide, a world leader in gases, technologies and services for Industry and Health, with Air Liquide operating the site. The PEM electrolyzer in Denmark is capable of supplying a fleet of more than 100 fuel cell electric vehicles per day and could contribute up to 0.5 percent of the transport sector greenhouse gas reduction targets in Denmark.

Douglas County – U.S.A.: Enabling utilities to store excess energy

Expected to be operational in 2021, this 5-megawatt PEM electrolyzer located in Douglas County in Washington state (U.S.A) will be the largest, as well as first of its kind in use by a public utility, in the United States. The new renewable hydrogen facility allows the Douglas County Public Utility District (PUD) to manufacture commercial hydrogen using electrolysis to harvest hydrogen from water from Wells Dam on the Columbia River. Cummins’ PEM electrolyzers, like Douglas County PUD’s electrolyzer, enables utilities to store the excess energy that they would typically sell off to the market at a financial loss, or not harness at all, and instead store that energy to sell into a new green hydrogen market. Additionally, it creates a way for utilities to engage in new market opportunities outside of their typical service area, removing growth barriers often faced in the industry. This project is made possible by legislation passed in Washington state in 2019, which authorized public utility districts to make and sell hydrogen.

Becancour – Canada: Building the largest PEM electrolysis plant in the world

Cummins is in the final stages of commissioning the largest PEM electrolysis plant in the world in Becancour, Canada for Air Liquide. The 20-megawatt facility will have an annual hydrogen output of approximately 3,000 tons. The electrolyzer will use renewable hydroelectricity to generate decarbonized, and green, hydrogen. The facility is planned to be operational in the coming months.

.png?itok=4l4mSi4l)

.jpg?itok=pRSU9UCO)

.png?itok=5--_fzBx)