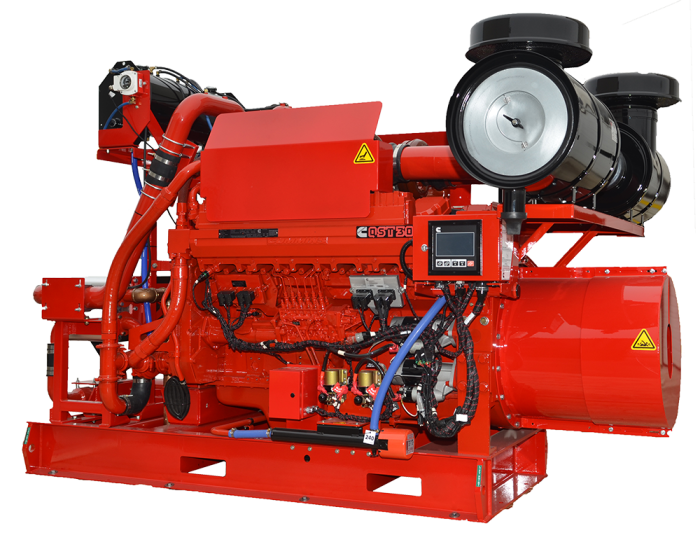

CFP30E

CFP30E

Power

907 - 1295

hp

676 - 966 kW

676 - 966 kW

Displacement

1860 cu in (30.5)

Certification

Modeled after the Cummins QST30, the CFP30 has higher torque, shorter service times, longer maintenance intervals, and increased fuel economy. Customers request this model due to the durability and compactness of the design which can be configured to meet most applications. Also one of the Cummins fire pump drive engines that offers flexibility to owners with its electronic-controlled Variable Speed Pressure Limiting Control (VSPLC) option.