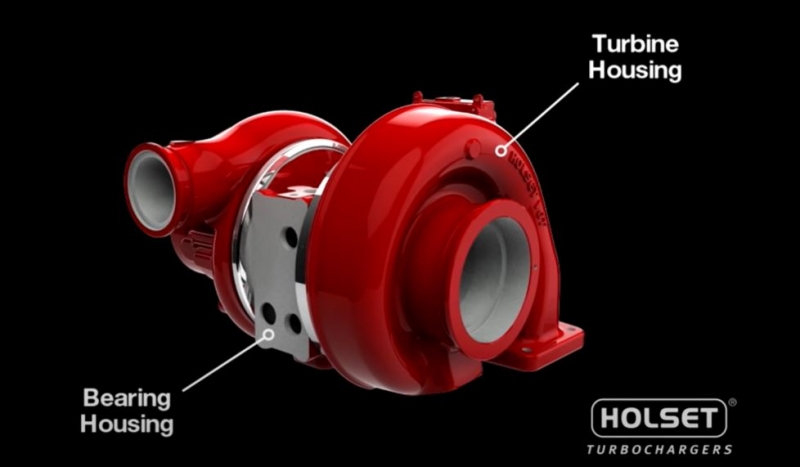

Cummins is the only manufacturer focused solely on medium- to heavy-duty diesel engine turbo technologies. For more than 60 years, we have delivered innovative, reliable turbocharger solutions for our customers. Our vision for turbocharger solutions, thanks to our rich company heritage derived from our Holset® brand, sets us apart as a technology leader.

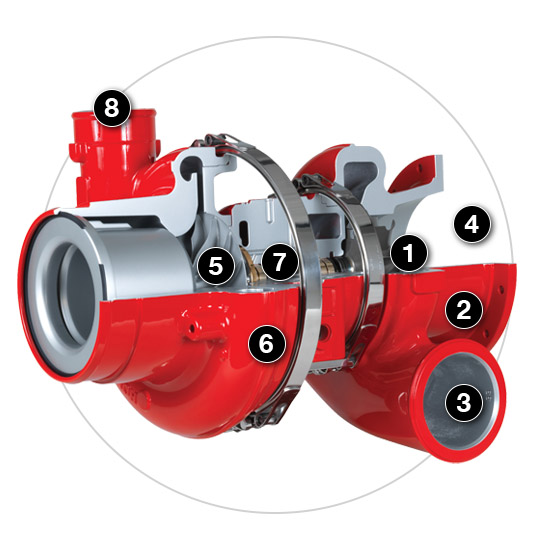

Commercial diesel engines require advanced technologies that deliver efficiency and meet strict emissions requirements. Our fixed, wastegate, variable, two-stage, turbo-compounding and waste heat expander technologies were specifically developed to deliver higher efficiency and lower cost.

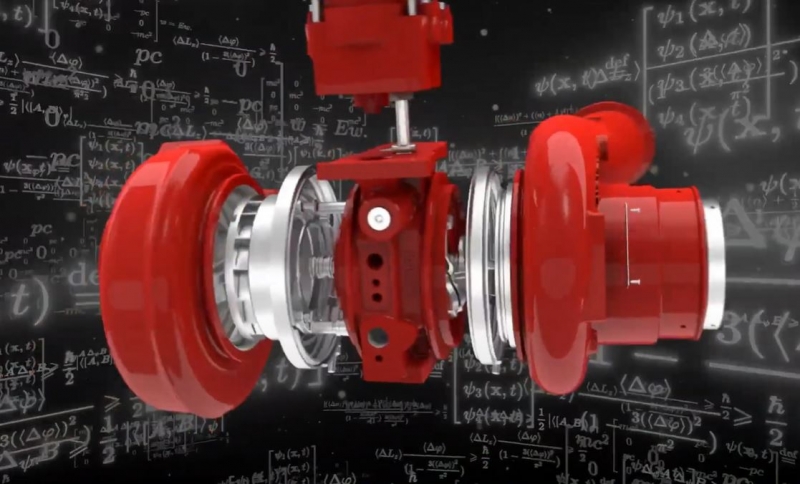

Today, Cummins Turbo Technologies engineers are actively developing state of the art solutions for the next generation, including assisted turbocharging, new bearing systems and enhanced compressor stage performance.